Test & Validation Services

TESTING, VALIDATION AND RELIABILITY ENGINEERING

Test and Validation at Aptiv

With locations in Europe and North America, over 200 employees, and 30 years of experience, Aptiv’s state-of-the-art test and validation laboratories offer high-quality testing services to provide detailed insights into product performance and durability for the automotive industry, consumer electronics, and beyond.

Unmatched Quality and Precision

Aptiv delivers precise, reliable results that support product innovation and regulatory compliance. Our laboratory helps products meet rigorous quality, accuracy and security requirements by operating in full compliance with a range of international standards, including:

- IATF 16949

- TISAX

- ASPICE

- ISO standards

- 9001

- 45001

- 14001

- 17025

Reliable Testing Solutions Tailored to Your Needs

Aptiv offers competitive pricing and fast turnaround times, providing exceptional value for our customers through quality, speed and expertise. Our laboratories are separated into four areas of specialization: EMC, Environmental, Vibroacoustics, and Failure Analysis. Each area is equipped with state-of-the-art facilities. Our staff has decades of experience in reliability engineering, automotive industry, testing and other related specialties. For more complex testing needs, we offer a full range of support options, including:

- Test specification review and test plan development

- Custom monitoring solutions

- Professional, detailed reports

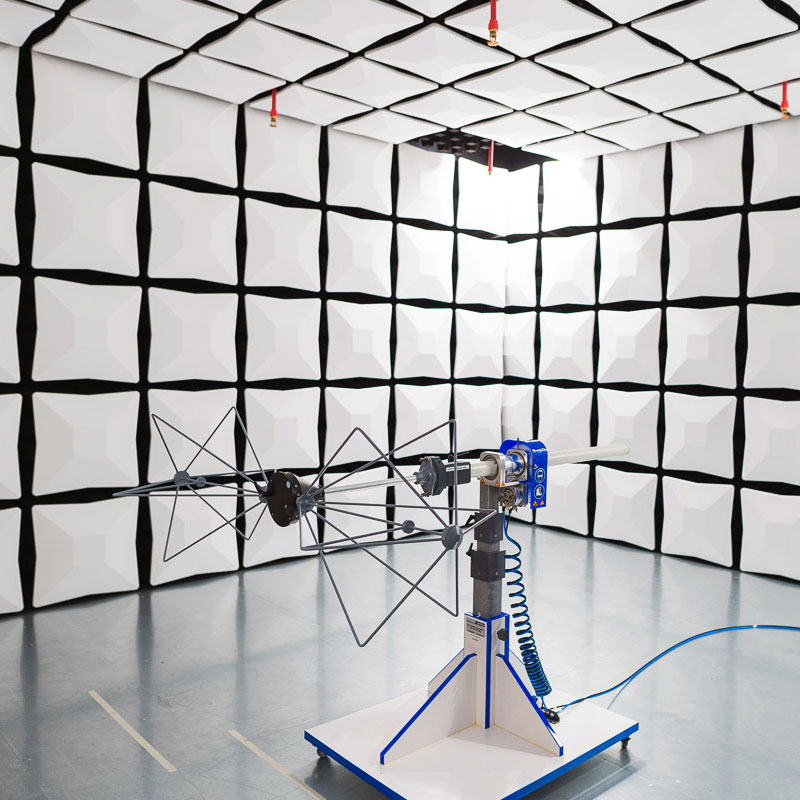

EMC Testing Laboratory

We offer comprehensive electromagnetic compatibility testing services, using our vast array of advanced testing equipment.

High performance ALSE chambers to support Radiated Emissions and Radiated Immunity Testing with a wide variety of transmit and measurement antennas to cover a large frequency range.

One-meter reverberation chamber with tuner to support automotive and military testing.

Multiple test stations with a wide range of equipment for testing conducted immunity, transient emissions, magnetic field immunity, magnetic field emissions, as well a wide range of electrical stress tests.

Temperature- and humidity-controlled environments fully equipped to perform ESD testing.

- ISO 10605

- CISPR 25

- MIL-STD-461

- SAE J5551-5

- ISO 11452 suite

- ISO 7637 suite

- ISO 16750 suite

- IEC 61000-4-4

- IEC 61000-4-5

Over 20 years of ISO 17025 accreditation by A2LA or PCA, which both have a mutual recognition arrangement with ILAC and a multilateral recognition arrangement with IAF. UN R10 capable.

Accredited or recognized by OEMs, including:

- Ford Motor Company

- Stellantis

- General Motors

- Jaguar

- Caterpillar

- BMW

- Mercedes

- Rivian

- ...and more

Laboratory data: TCK Validation - EMC Laboratory ul. Podgórki Tynieckie 2; 30-399 Kraków

Accreditation number: AB 1637

Date of accreditation granting: 06-03-2017

Testing field: EMC (F)

Objects: Electrical products and equipment, telecommunications, electronics

A2LA Accredited Laboratory: Aptiv Westfield Test Lab – EMC Laboratory 17001 Oak Ridge Road, Westifield, IN 46704, USA

Accredited Since 2002

Accreditation number: 1567-03

View Accreditation Scope

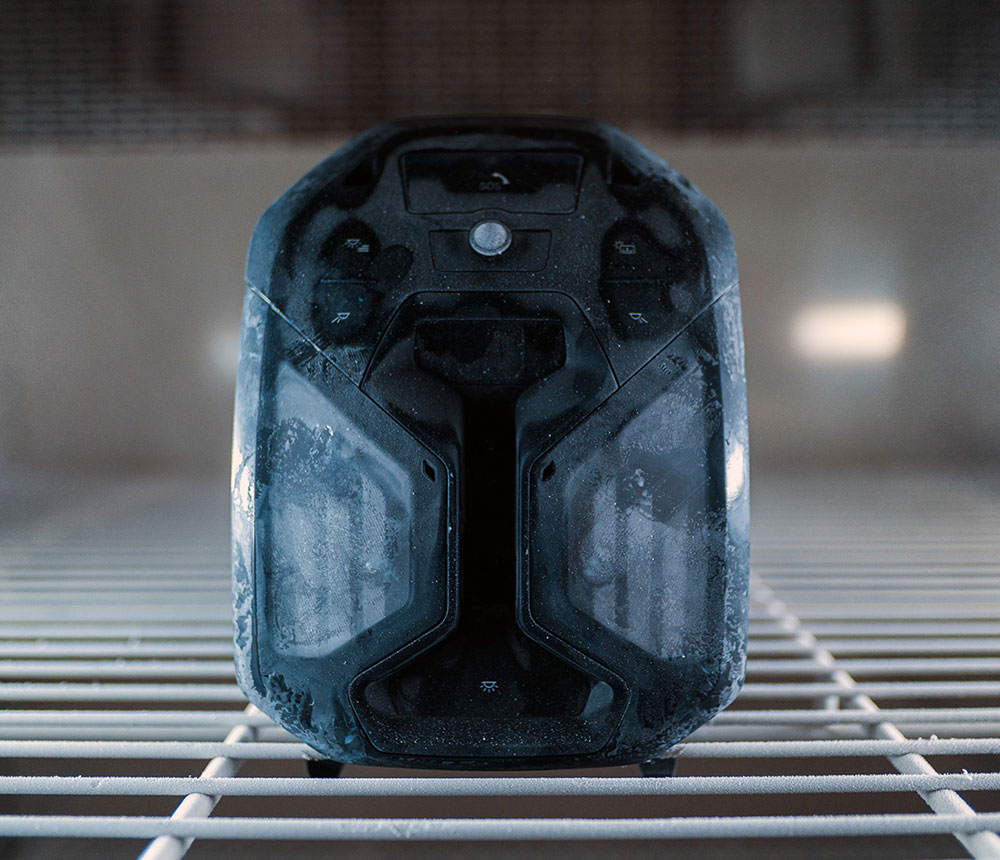

Environmental Testing Laboratory

Our Environmental laboratory offers testing services that include:

With over 80 climatic and thermal shock chambers, our laboratory offers services for a wide range of component sizes, accommodating volumes from 350 liters to 2,000 liters.

Includes comprehensive application of chemical agents as well as corrosive gas tests, simulating harsh environmental conditions to evaluate material resilience.

Testing is available with precise force-travel measurement capabilities, covering push-button and display aging under temperature-controlled conditions.

Testing includes salt spray tests, compliant with requirements from all major automotive manufacturers, ensuring robust performance against corrosion.

Evaluates components’ resistance to water and dust intrusion, ensuring reliability in demanding environments.

ISO 17025 accreditation by A2LA or PCA, which both have a mutual recognition arrangement with ILAC and a multilateral recognition arrangement with IAF.

Laboratory data: TCK Validation - Environmental Laboratory ul. Podgórki Tynieckie 2; 30-399 Kraków

Accreditation number: AB 1899

Date of accreditation granting: 26-04-2024

Testing field: Physical testing (N)

Objects: Electrical products and equipment, telecommunications, electronics

View Accreditation Scope

A2LA Accredited Laboratory: Aptiv Westfield Test Environmental Laboratory 17001 Oak Ridge Road, Westifield, IN 46704, USA

Accredited Since 2002

Accreditation number: 1567-03

View Accreditation Scope

Vibroacoustics Testing Laboratory

- Test range up to 21g (RMS) for random, 30g (Peak) for sine and 100g shock tests

- Vibration tests capability combined with temperature and humidity -40°/+120°C

- Medium force shakers with 2in stroke and horizontal tests capability on ~1m2 slip tables

- Squeak and rattle tests with noise measurement and recordings for Automotive industry

- Vibroacoustic tests capability on MB Black shaker with horizontal table in Semi Anechoic chamber

- Sound Pressure Level, Sound Power and low noise measurements

- Subjective evaluation according to Customer scales and requirements

- Noise source identification of electronic components

ISO 17025 accreditation by A2LA or PCA, which both have a mutual recognition arrangement with ILAC and a multilateral recognition arrangement with IAF.

Laboratory data: Vibroacoustics Testing Laboratory ul. Podgórki Tynieckie 2; 30-399 Kraków

Accreditation number: AB 1860

Date of accreditation granting: 27-03-2023

Testing field: Acoustics and noise testing (A)

Objects: Electrical products and equipment, telecommunications, electronics, other products

View Accreditation Scope

A2LA Accredited Laboratory: Aptiv Westfield Test Laboratory 17001 Oak Ridge Road, Westifield, IN 46704, USA

Accredited Since 2002

Accreditation number: 1567-03

View Accreditation Scope

Failure Analysis Laboratory

Our Failure Analysis laboratory has an array of specialized equipment to perform a variety of inspection and analysis techniques.

Optical equipment with enhanced image resolution, multiple angles of observation, and 3D capabilities to review the appearance of the product and document defects.

Assessment of the quality of a primary circuit board’s internal layers, connections and overall construction to ensure reliability and functionality of electronic devices. Identification of issues such as cracks, voids, insufficient plating, delamination, and solder defects.

A non-destructive inspection to identify failures in both the complete assembly and individual components.

A powerful technique to analyze and verify the cleanliness of printed circuit board assemblies (PCBAs).

A powerful technique used in printed circuit board (PCB) failure analysis and other applications to examine the surface and composition of materials at a microscopic level. Scanning Electron Microscopy (SEM) provides high-resolution images while Energy Dispersive X-Ray Spectroscopy (EDS) identifies the elemental composition of the analyzed area. This combination allows for detailed imaging and analysis of PCB components, including failure analysis, dimensional analysis, and identification of contaminants.

- Materials Properties Analysis

- Fourier Transform Infrared Spectroscopy (FT-IR)

- Harness/Microhardness Test

- Texture Analysis

- Microtome

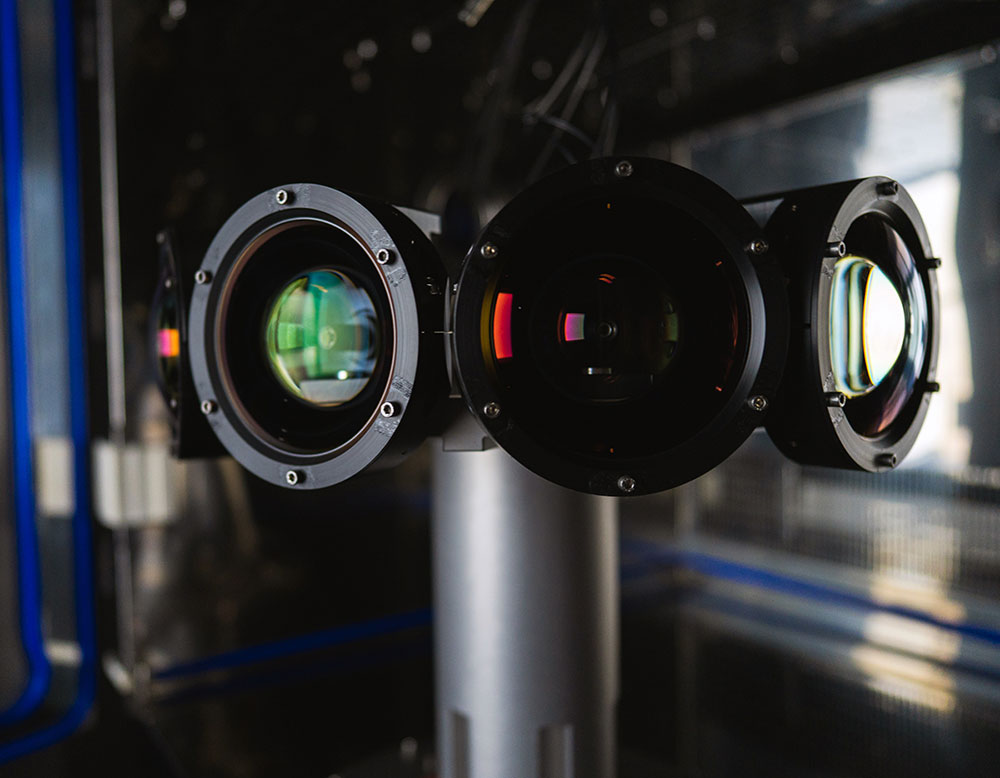

Automated Test System development

Aptiv offers comprehensive services for designing, developing, and constructing test systems, from concept to turnkey systems.

A wide range of equipment to support automatic testing: RF generator (FM, AM, HD, XM, SDARS, RDS), GNSS signal (full scope), WLAN/BT, Real Target Simulator (radars), Camera Testing System.

Systems dedicated to EMC testing offering full optical isolation and compliance with low ambient requirements. System automation provided in cooperation with Rohde & Schwarz. EMC32/Elektra.

Simulation of the complete environment of the tested unit. Support for communication buses: CAN, LIN, FlexRay, Tx, T1, MOST, UART, and many other protocols.

Hardware simulation of the unit's environment using real/original and simulated loads of the tested unit. Support for air and liquid cooling units.

Parametric (EndPoint), long duration environmental test (Continuous Monitoring), durability (3D-VM), and functional test benches.

Results are automatically evaluated, and data parameters are fully recorded for in-depth analysis.

Our broadly experienced engineering team provides interdisciplinary solutions to challenges.

Get Started

To get started, email us your test requirements, product description and timeframe. An experienced validation engineer will reach out to confirm your needs and manage your project until completion. We will confirm our capacity and capability for your request and provide a detailed quote.

Once you deliver your test samples to our laboratory, we will perform the tests according to your requirements and provide a comprehensive test report upon completion.