Smart Vehicle Architecture: Key to the Future of Automotive Sustainability

100+ controllers in every vehicle. 200 million lines of code. More than 1,000 automotive functions dependent on multiple controllers. The numbers speak for themselves. Today’s automotive systems built on traditional architectures have become too hard to design, develop, validate and maintain. To efficiently and affordably integrate new features such as higher levels of automation and electrification into the vehicles of today and tomorrow, automakers need something new: a sustainable platform we call Smart Vehicle Architecture™ (SVA).

SVA: Addressing challenges throughout the vehicle lifecycle.OEMs face significant challenges today at every stage of a vehicle’s lifecycle. In the development phase, they face increasing complexity from feature and controller interdependence that results in longer and more expensive development cycles. In the manufacturing phase, increasingly large and unwieldy physical components make manual assembly difficult and automation almost impossible. And in the post-production phase, once vehicles are out on the road, component changes bring even more complexity, impeding engineers’ ability to add feature enhancements.

Three challenges. One solution.With SVA, you can create independent lifecycles, faster software launches and simpler hardware validation and updates when needed. Plus, fully defined interfaces simplify software development and hardware interaction.

SVA allows you to remove the input/output (I/O) from expensive domain controllers and place them in zone docking stations, while also utilizing ring networks and topologies to optimize power and data distribution.

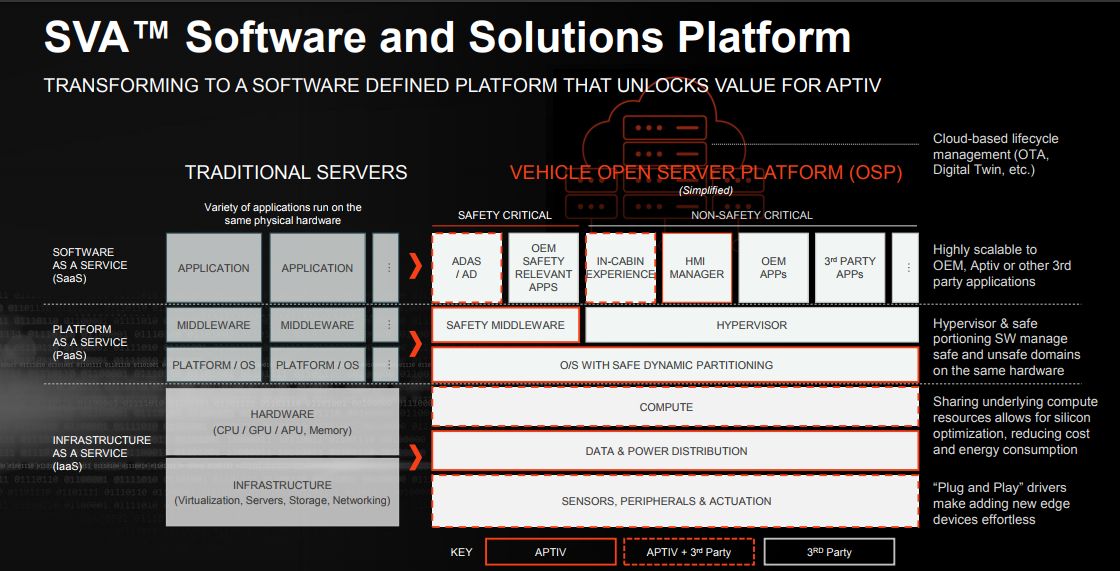

With SVA, you can centralize compute functionality into four or five physical compute platforms while enabling resource-sharing by operating logically as one central compute “cluster”.

SVA: Simple + Scalable = Sustainable

Simply put, these three SVA solutions address today’s main technical limitations, with the result being a sustainable architecture over the life of the vehicle and platform.

A software-defined platform unlocks value for everyone..

A software-defined platform unlocks value for everyone..In short, SVA is the sum of all our parts: the brain and the nervous system of the vehicle, the application of our full-stack solutions capability, and the unique ability to conceive, specify and deliver end-to-end architecture solutions for all three layers.

Paving the path toward adoption.