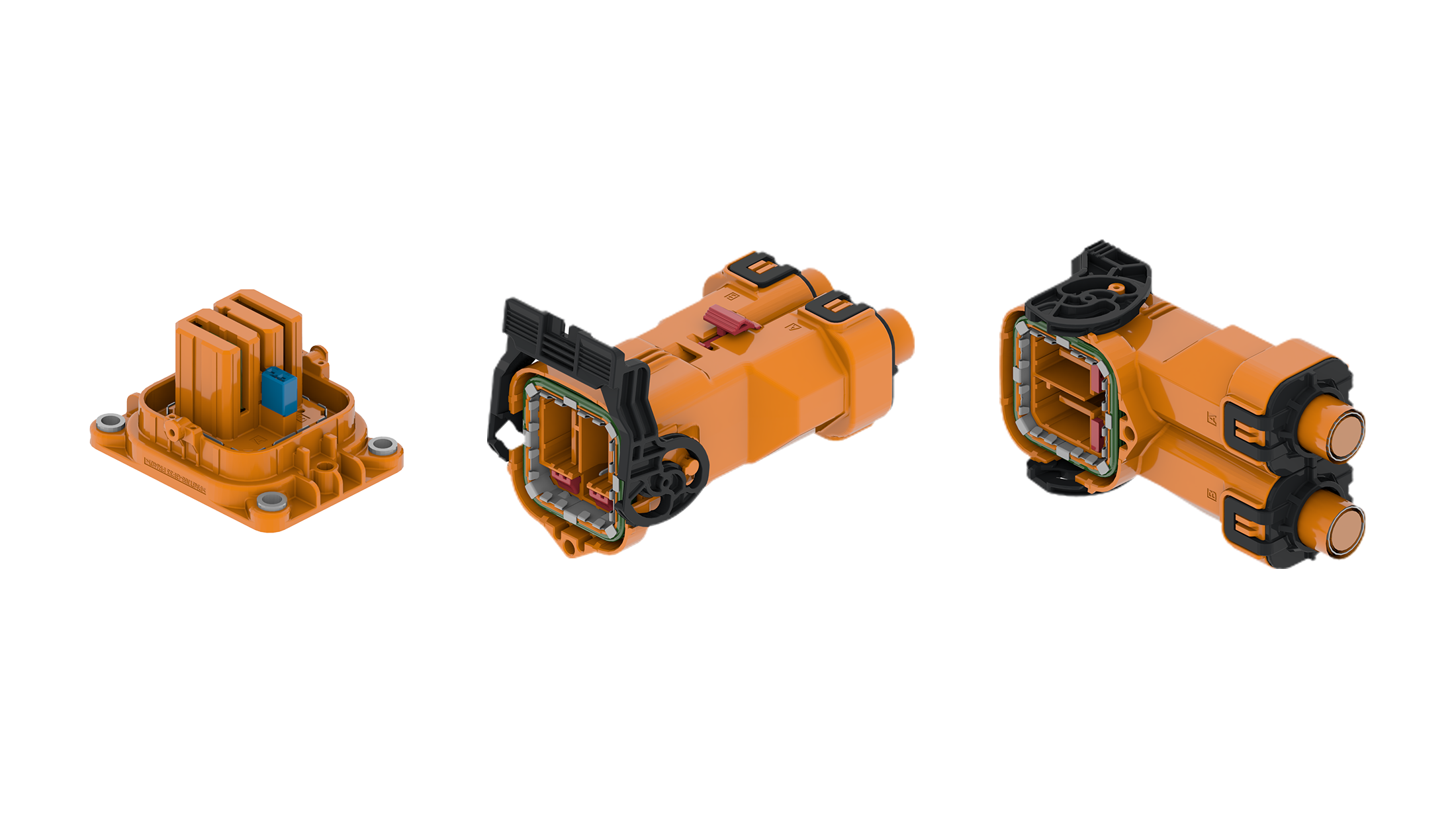

A Robust, Compact High-Voltage Interconnect Solution

As automakers unveil one battery-electric vehicle (EV) platform after another, high-voltage interconnects are emerging as one of the most important automotive components. They have to conduct electricity efficiently, save space and last a long time — while also streamlining manufacturing and adapting to a range of applications. Aptiv’s DCT™ interconnects with direct contact technology help OEMs to achieve their ultimate goals of greater reliability, range and performance.

DCT™ Series Benefits

DCT™ 1400 Series Overview and Performance

More About DCT™

Why Choose DCT™ ?

Get details about the many advantages of Aptiv connectors with DCT in this PDF.

download

Direct Contact Technology Needed to Meet Future EV Needs

In this in-depth white paper, learn how DCT™ helps OEMs to achieve their ultimate goals of greater reliability, range and performance.

Why Choose Aptiv?

Discover our broad portfolio that covers the full spectrum of architecture electrification solutions.